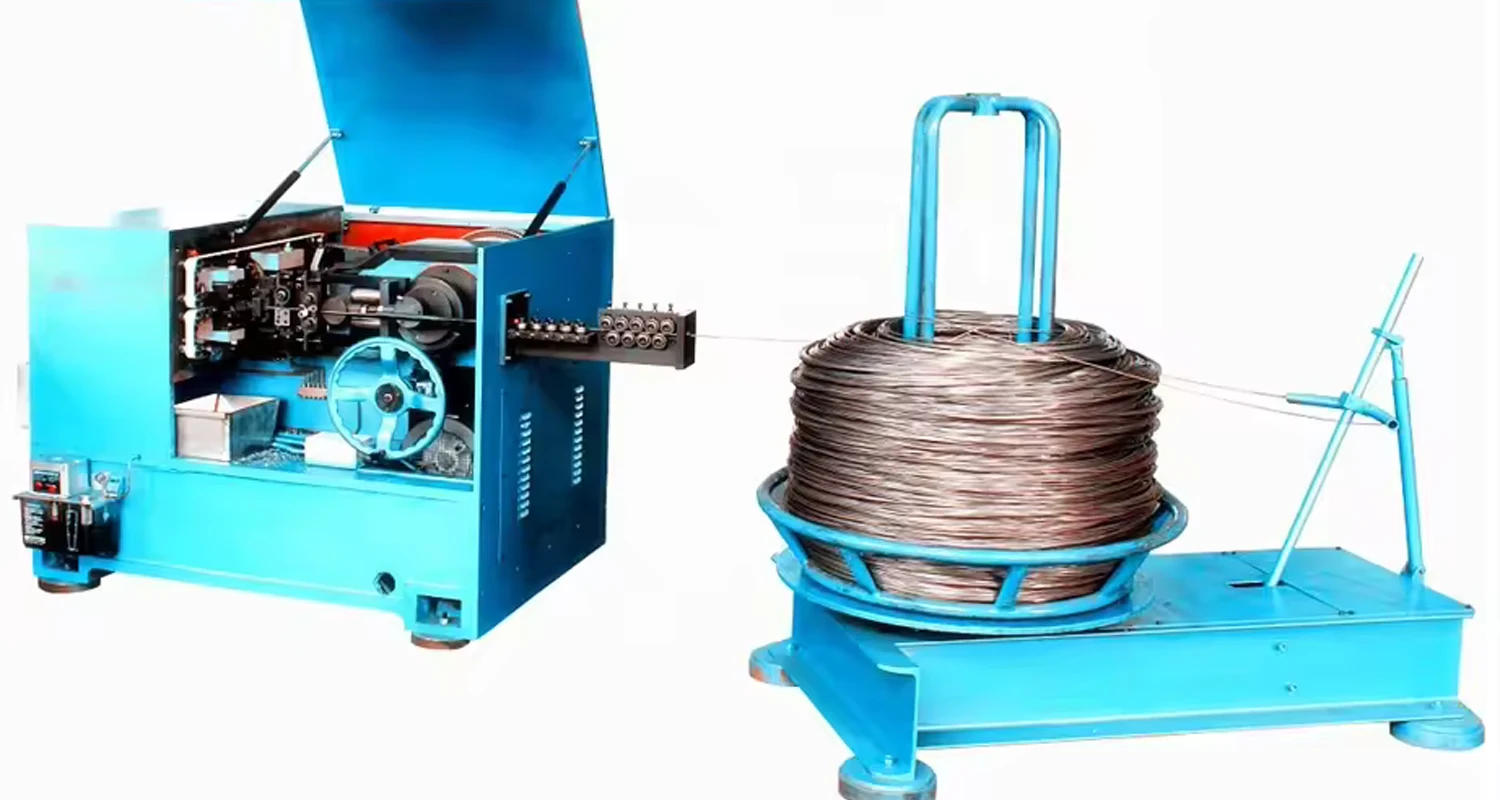

The Essential Raw Material for Nail Manufacturing.

Nail Making Wire is a specialized low-carbon steel wire rod, meticulously engineered to be drawn into the precise diameters required for automated nail production. Its consistent chemical composition, surface quality, and ductility are critical for enabling high-speed manufacturing of strong, reliable nails with minimal machine downtime.

Controlled Chemical Composition: Typically a low-carbon steel (e.g., AISI 1006-1010) that balances formability for heading with the required final strength.

Precise Dimensional Tolerance: Drawn to extremely tight diameter tolerances to ensure consistent feeding and operation in high-speed nail making machines.

Superior Surface Finish: A smooth, defect-free surface is essential to reduce friction in the dies, prevent jamming, and extend tool life.

Optimized Ductility: Annealed to a specific temper to allow for the cold-heading and point-forming processes without cracking or breaking.

Uniform Spooling: Wound onto large, tangle-free spools or coils for continuous, uninterrupted feeding into production machinery.

Grade:SAE1006-1080,Q195,WA1010,SWRH32-37,SWRH42A-77A,SWRH42B-82B

Size:5.5mm 6.5mm 8mm 9mm 10mm 11mm 12mm 13mm

Standard:ASTM,DIN,GB,JIS

Weight of each package:1.9-2.3 tons,according to request

Packing:In coils, loading in container or by bulk vessel

Application:Drawing, construction materials, machinery parts, construction for Houses, Bridges, Roads.

Weight Varies By Profile

Mill Certification: Guaranteed to meet specific industry standards (e.g., ASTM, JIS, DIN) with certified chemical and mechanical properties.

Bright Finish: A clean, uncoated surface, standard for most general-purpose nail production.

Copper-Coated: A thin copper coating acts as a lubricant and corrosion inhibitor during the wire drawing process, also aiding in the nail-making operation.

Annealed in Process: The wire is supplied in a spheroidized annealed condition, making it soft and ideal for cold forming.

Common Nail Production: The primary raw material for manufacturing a vast range of common, box, and sinker nails.

Finish & Brad Nail Manufacturing: Drawn to finer gauges for producing finish nails, brads, and pins.

Specialty Nail Fabrication: Used to create concrete nails, roofing nails, and other specialty fasteners with specific strength requirements.

Staple & Upholstery Pin Production: Also serves as the base material for making staples and other small, wire-formed fasteners.

Commercial

Industrial

Common Steel Color

We are committed to fostering enduring partnerships with our clients. Recognizing the unique needs of each customer, we offer customized solutions tailored to their specific requirements. With a focus on flexibility in order processing and punctual delivery, we are dedicated to ensuring customer satisfaction and establishing long-term collaborations built on trust and reliability.

Thank you for your interest in our factory. Should you have any inquiries or require further information regarding our roofing sheets or related services, please feel free to reach out to us. We eagerly anticipate the opportunity to collaborate with you and contribute to your success.

Take the next step – contact one of our experts or explore our full line of metal roof systems.