PPGI and PPGL are both types of steel sheets that are commonly used in various industries, including construction, automotive, and appliances. The main difference between PPGI (Pre-Painted Galvanized Iron) and PPGL (Pre-Painted Galvalume) sheets lies in the coating material and its composition. Here’s a breakdown of the key distinctions:

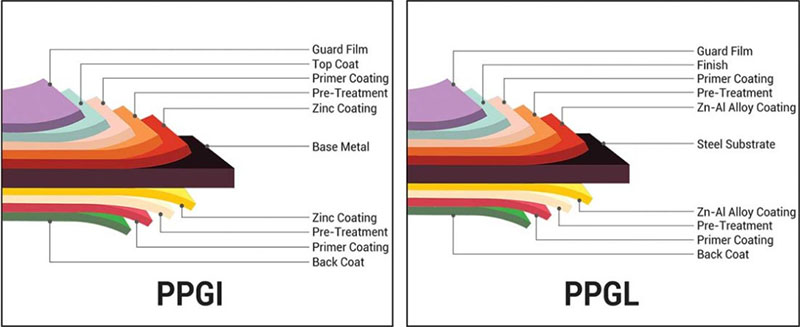

1.Coating Material:

- PPGI: PPGI sheets are coated with zinc on the outer surface, which provides excellent corrosion resistance. The zinc coating helps protect the underlying steel from rust and corrosion.

- PPGL: PPGL sheets, on the other hand, are coated with a combination of zinc and aluminum (zinc-aluminum alloy), commonly referred to as Galvalume. This coating offers enhanced corrosion resistance compared to PPGI.

2.Composition:

- PPGI: PPGI sheets consist of a base metal, usually cold-rolled steel or galvanized steel, with a zinc coating applied on top. This zinc layer acts as a sacrificial barrier, protecting the underlying steel from corroding.

- PPGL: PPGL sheets are typically made of cold-rolled steel or galvalume steel, which is a combination of steel substrate and a zinc-aluminum alloy coating. The aluminum in the coating provides additional corrosion protection.

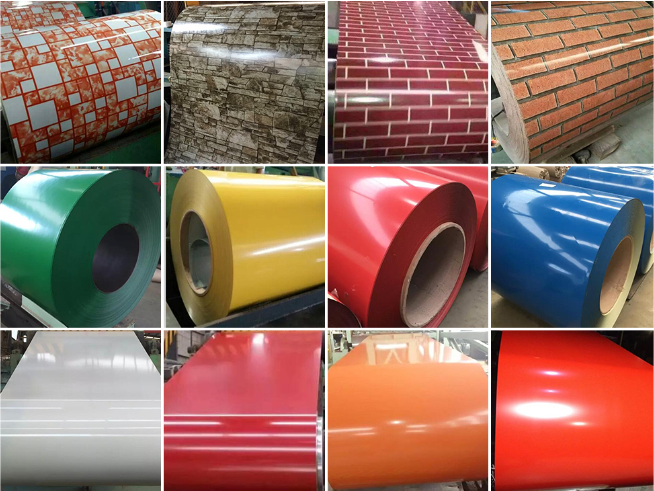

3.Appearance:

- PPGI: PPGI sheets are available in a wide range of colors and finishes. They are known for their vibrant, glossy appearance, making them suitable for applications where aesthetics are important, such as architectural cladding.

- PPGL: PPGL sheets also come in various colors and finishes, but they tend to have a slightly different appearance compared to PPGI. The presence of aluminum in the coating can give PPGL sheets a different texture and visual effect.

4.Application:

- PPGI: PPGI sheets are commonly used in applications that require good corrosion resistance, such as roofing, wall cladding, garage doors, and appliances.

- PPGL: PPGL sheets are particularly suitable for environments that require higher corrosion resistance, such as coastal areas or places with high humidity. They are commonly used in roofing, walling, and other outdoor applications.

It’s worth noting that while PPGI and PPGL have different coating materials, their underlying steel substrates can be similar. The choice between PPGI and PPGL depends on the specific requirements of the application, including the level of corrosion resistance needed and the desired appearance.