There are several types of thermal insulation sheets used for roofing, each with its own properties and advantages. Here are some of the most common types:

1. Polyurethane Foam (PUF) Sheets

- Properties:

- High R-value per inch (R-6 to R-7).

- Closed-cell structure providing excellent moisture resistance.

- Lightweight and durable.

- Advantages:

- Provides high thermal resistance with a thinner layer.

- Acts as both a thermal barrier and moisture barrier.

- Easy to handle and install.

- Applications:

- Commonly used in residential and commercial buildings.

- Ideal for insulating flat and pitched roofs, as well as ceilings and walls.

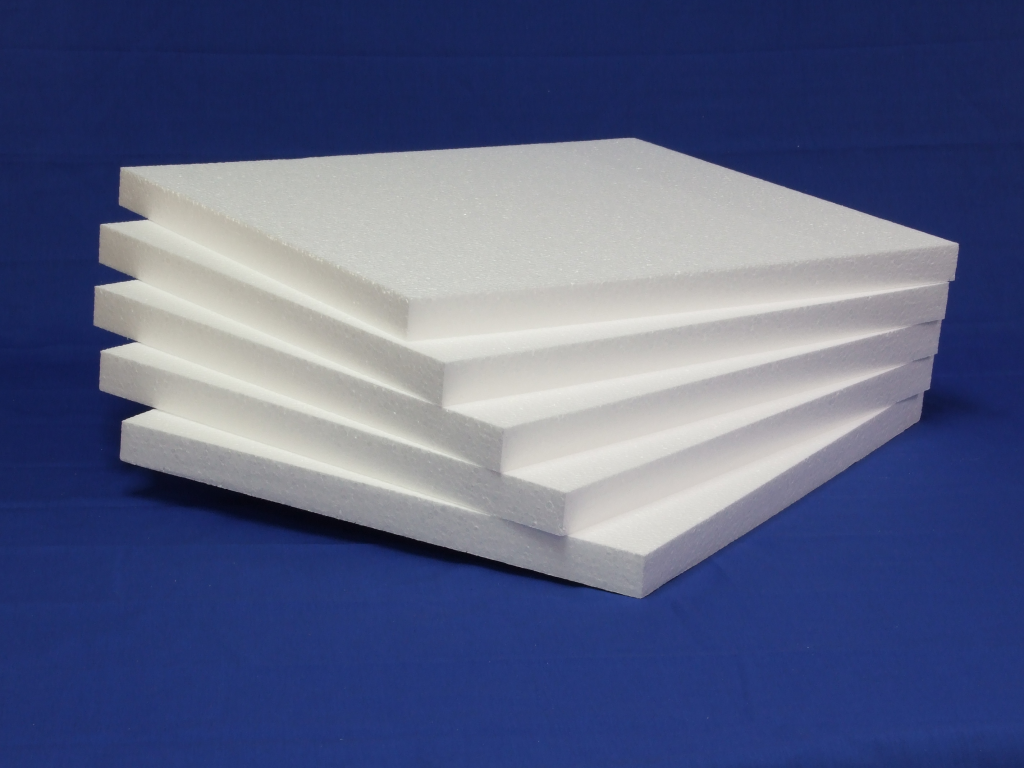

2. Expanded Polystyrene (EPS) Sheets

- Properties:

- R-value around R-4 per inch.

- Lightweight and rigid.

- Easily cut to fit various shapes and sizes.

- Advantages:

- Cost-effective and widely available.

- Good insulation performance for the price.

- Resistant to moisture and decay.

- Applications:

- Used in roofing, walls, floors, and basement insulation.

- Common in commercial building roofs and exterior insulation systems.

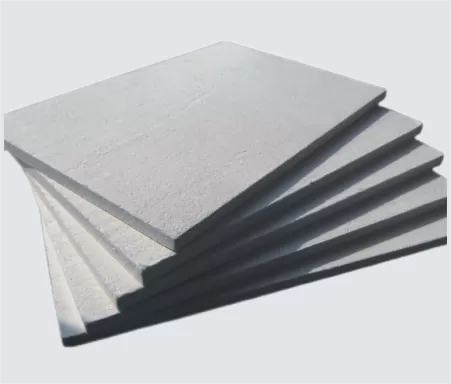

3. Extruded Polystyrene (XPS) Sheets

- Properties:

- Higher R-value than EPS, around R-5 per inch.

- More uniform cell structure.

- Strong compressive strength.

- Advantages:

- Excellent moisture resistance, making it suitable for below-grade applications.

- Higher thermal performance than EPS.

- Durable and long-lasting.

- Applications:

- Used in roofs, walls, foundations, and below-grade applications.

- Ideal for inverted roofs and applications exposed to moisture.

4. Glass Wool (Fiberglass) Sheets

- Properties:

- R-value ranges from R-2.2 to R-4.3 per inch.

- Made from recycled glass and sand.

- Non-combustible and resistant to fire.

- Advantages:

- Excellent thermal and acoustic insulation properties.

- Resistant to mold, mildew, and pest infestation.

- Cost-effective and widely available.

- Applications:

- Used in roofing, attic insulation, walls, and HVAC systems.

- Common in residential and commercial buildings.

5. Mineral Wool (Rock Wool) Sheets

- Properties:

- R-value around R-3.7 to R-4.3 per inch.

- Made from natural rock or slag.

- Non-combustible with a high melting point.

- Advantages:

- Superior fire resistance and acoustic insulation.

- Water-resistant but vapor-permeable.

- Environmentally friendly, often made from recycled materials.

- Applications:

- Ideal for fire-rated roofs and walls.

- Used in industrial and commercial buildings.

- Suitable for soundproofing applications.

6. Reflective Insulation Sheets

- Properties:

- Consist of aluminum foil layers combined with polyethylene or bubble wrap.

- Reflective surface reduces radiant heat transfer.

- Lightweight and flexible.

- Advantages:

- Reduces heat gain in hot climates by reflecting solar radiation.

- Easy to install and handle.

- Provides additional moisture barrier properties.

- Applications:

- Used in roofs, attics, walls, and crawl spaces.

- Particularly effective in hot and sunny climates.

7. Polyisocyanurate (PIR) Sheets

- Properties:

- High R-value, around R-6 to R-6.5 per inch.

- Closed-cell foam structure.

- Often faced with foil or fiberglass for added durability.

- Advantages:

- Superior thermal resistance.

- Good fire resistance and low smoke emission.

- Moisture-resistant.

- Applications:

- Suitable for a wide range of roofing systems.

- Used in commercial, industrial, and residential buildings.

- Ideal for applications requiring high thermal performance.

8. Vacuum Insulation Panels (VIPs)

- Properties:

- Very high R-value, up to R-50 per inch.

- Core material typically made of fumed silica or glass fiber.

- Encapsulated in a gas-tight envelope.

- Advantages:

- Extremely high thermal efficiency.

- Thin profile allows for insulation in tight spaces.

- Lightweight and easy to handle.

- Applications:

- Used in high-performance building envelopes.

- Ideal for retrofitting and space-constrained applications.

- Common in commercial and industrial buildings.

9. Natural Fiber Insulation Sheets

- Properties:

- Made from renewable resources like cellulose, sheep wool, or hemp.

- R-value varies by material (e.g., cellulose: R-3.2 to R-3.8 per inch).

- Biodegradable and environmentally friendly.

- Advantages:

- Sustainable and eco-friendly.

- Good thermal and acoustic insulation properties.

- Safe to handle with minimal health risks.

- Applications:

- Used in green building projects and sustainable construction.

- Suitable for roofs, walls, and floors in residential buildings.

10. Aerogel Insulation Sheets

- Properties:

- Extremely low thermal conductivity, around R-10 to R-30 per inch.

- Made from silica aerogel, one of the lightest solid materials.

- Hydrophobic and fire-resistant.

- Advantages:

- Very high insulation performance with a thin profile.

- Lightweight and easy to install.

- Resistant to moisture and fire.

- Applications:

- Used in high-performance building envelopes.

- Suitable for applications requiring superior insulation in limited spaces.

- Common in industrial and aerospace applications.

Each type of insulation sheet offers unique benefits and is suitable for different applications depending on factors such as thermal performance requirements, budget, installation constraints, and environmental considerations.