The production process of color steel coils involves several steps, combining the metallurgical process of steelmaking with advanced coating technologies to produce high-quality, durable, and aesthetically pleasing steel sheets. Here’s a detailed overview of the process:

1. Base Steel Production

a. Steel Making

- Blast Furnace: Iron ore is reduced to molten iron in a blast furnace using coke (carbon) as a reducing agent.

- Basic Oxygen Furnace (BOF) / Electric Arc Furnace (EAF): The molten iron is refined to produce steel. In the BOF, oxygen is blown into the molten iron to remove impurities. In the EAF, recycled steel scrap is melted using electric arcs.

b. Casting

- Continuous Casting: The molten steel is poured into a continuous casting machine, where it solidifies into semi-finished slabs.

2. Hot Rolling

a. Reheating

- Reheat Furnace: The steel slabs are heated to approximately 1200°C in a reheat furnace to make them malleable.

b. Rolling

- Roughing Mill: The reheated slabs are passed through a roughing mill to reduce thickness.

- Finishing Mill: Further rolling in the finishing mill achieves the final thickness and desired width. The steel is then cooled using water sprays.

c. Coiling

- Coiling: The hot-rolled steel is wound into large coils for transport to the next processing stage.

3. Cold Rolling

a. Pickling

- Pickling Line: The hot-rolled coils are pickled in an acid bath to remove oxides and scale.

b. Cold Rolling

- Cold Rolling Mill: The pickled steel is rolled at room temperature to the desired thickness. This increases the strength and improves surface finish.

c. Annealing

- Batch Annealing: The cold-rolled coils are annealed in a furnace to recrystallize the steel and restore ductility.

- Continuous Annealing: An alternative process where the steel is continuously heated and cooled as it passes through a furnace.

4. Surface Cleaning and Preparation

a. Cleaning

- Alkaline Cleaning: The steel surface is cleaned with alkaline solutions to remove grease, oil, and dirt.

b. Surface Treatment

- Mechanical Treatment: Techniques such as brushing or shot blasting to create a rough surface for better coating adhesion.

- Chemical Treatment: Application of solutions such as phosphates or chromates to enhance corrosion resistance and coating adherence.

5. Coating Application

a. Pretreatment

- Chemical Conversion Coating: A thin layer of phosphate or chromate is applied to improve corrosion resistance and adhesion of subsequent layers.

b. Primer Coating

- Roller Coating: A primer is applied to the pretreated surface using roller coaters. The primer is usually epoxy-based for excellent adhesion and corrosion resistance.

c. Topcoat Application

- Topcoat: A topcoat of paint is applied over the primer. This layer provides the final color, gloss, and additional protection. Common topcoat types include polyester, silicon-modified polyester (SMP), polyvinylidene fluoride (PVDF), and plastisol.

- Roller Coating: The topcoat is applied using roller coaters for uniform thickness and smooth finish.

d. Curing

- Oven Curing: The coated steel passes through a curing oven where it is heated to a specified temperature (typically around 200-250°C) to cure and harden the coatings.

6. Quality Control and Inspection

a. Visual Inspection

- Surface Examination: Inspectors check for surface defects such as scratches, dents, or coating inconsistencies.

b. Testing

- Color Measurement: Spectrophotometers are used to ensure the color meets specifications.

- Thickness Gauging: Non-destructive methods like electromagnetic induction measure coating thickness.

- Adhesion Testing: Tests like cross-hatch or pull-off adhesion tests ensure the coating is firmly bonded.

- Corrosion Testing: Salt spray tests and other methods simulate environmental exposure to check for corrosion resistance.

7. Finishing

a. Trimming

- Edge Trimming: The coils are trimmed to remove any irregular edges.

b. Slitting

- Slitting Line: The wide coils are slit into narrower strips as required.

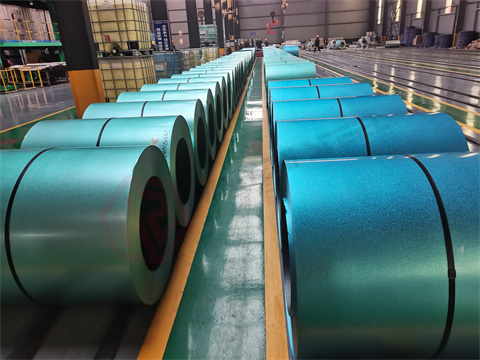

c. Recoiling

- Recoiling: The processed steel is recoiled to the desired length and width.

8. Packaging and Shipping

a. Protective Packaging

- Wrapping: The coils are wrapped in protective materials such as plastic or waterproof paper to prevent damage and corrosion during transportation.

- Palletizing: Coils are placed on pallets or crated for additional protection.

b. Labeling

- Labeling: Each coil is labeled with relevant information such as grade, coating type, color, and batch number.

c. Logistics

- Shipping: The packaged coils are loaded onto trucks, ships, or trains for delivery to customers.

Each step in this process is critical to ensuring the final product meets the desired standards for appearance, durability, and performance. The exact procedures and technologies used can vary depending on the specific requirements and the capabilities of the manufacturing facility.