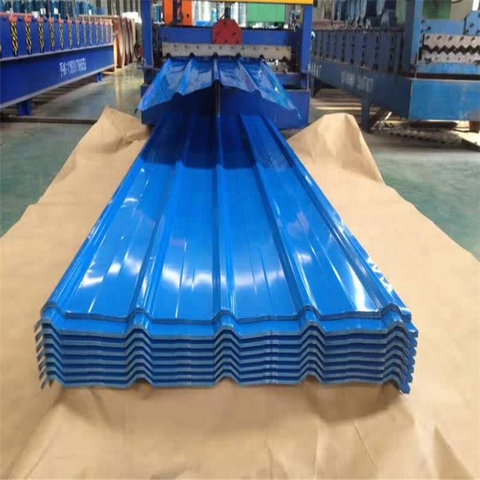

A color steel sheet is a type of steel that is coated with a layer of paint or other protective finish. This coating serves multiple purposes, including protection against corrosion, enhancing aesthetic appeal, and providing resistance to various environmental factors.

The coating on a color steel sheet serves several critical functions, enhancing the performance and durability of the steel. These functions include:

- Corrosion Resistance:

- Barrier Protection: The coating acts as a physical barrier that prevents moisture, oxygen, and other corrosive agents from reaching the steel surface. This is crucial in environments where the steel is exposed to humidity, rain, or industrial pollutants.

- Galvanic Protection: Some coatings include zinc or other sacrificial metals that provide galvanic protection. These metals corrode preferentially, protecting the steel underneath.

- Aesthetic Appeal:

- Color Variety: Coatings can be formulated in a wide range of colors and finishes, from matte to glossy, allowing for customization according to architectural preferences and branding needs.

- Consistency: The coating ensures a uniform appearance across large surfaces, which is important for large-scale applications like roofing and wall cladding.

- Weather Resistance:

- UV Resistance: Many coatings contain UV-resistant compounds that prevent degradation from sunlight exposure. This reduces fading and degradation of the material.

- Temperature Tolerance: The coatings are designed to withstand thermal expansion and contraction due to temperature changes, preventing cracking and peeling.

- Chemical Resistance:

- Protection in Harsh Environments: Coatings provide resistance against acids, alkalis, and other chemicals. This is especially important in industrial areas or coastal regions where exposure to harsh chemicals is common.

- Specialized Formulations: For specific applications, coatings can be tailored to resist particular chemicals or pollutants prevalent in the environment where the steel will be used.

- Mechanical Protection:

- Scratch and Abrasion Resistance: The coatings are formulated to be tough and durable, offering protection against mechanical damage during transportation, installation, and use.

- Impact Resistance: Some coatings provide additional impact resistance, which helps in preventing dents and other forms of mechanical damage.

- Ease of Maintenance:

- Self-Cleaning Properties: Certain coatings have hydrophobic properties that cause water to bead up and roll off, taking dirt and debris with it. This reduces the need for frequent cleaning.

- Stain Resistance: High-quality coatings resist staining from environmental pollutants, making it easier to maintain a clean appearance.

Types of Coatings and Their Specific Benefits

- Polyester (PE): Offers good durability and a variety of colors. It is cost-effective and widely used for roofing and siding.

- Silicone Modified Polyester (SMP): Provides enhanced durability and resistance to weathering, with better color retention and gloss compared to standard polyester.

- Polyvinylidene Fluoride (PVDF): Known for exceptional weather resistance, UV stability, and long-lasting color retention. It is often used in high-end architectural projects.

- Epoxy Coatings: Offer excellent adhesion and corrosion resistance, often used as primers under other coating systems.

- Polyurethane (PU): Provides good abrasion resistance and flexibility, making it suitable for environments with high mechanical wear.

Applications

- Construction: Used in roofing, wall cladding, facades, and structural components, where both aesthetic and protective properties are essential.

- Industrial: Applied in manufacturing facilities and warehouses for both structural and protective purposes.

- Automotive: Used in the manufacturing of vehicle components, offering both corrosion protection and aesthetic appeal.

- Agricultural: Utilized in the construction of barns, silos, and other agricultural buildings where durability against environmental factors is crucial.

In summary, the coating on color steel sheets is a multifunctional component that significantly enhances the performance, durability, and appearance of the steel, making it a versatile and valuable material in various industries.